The Role of Robots in Injection Molding

When we refer to robots in injection molding we mean the sort of machines that are capable of tasks on their own. These robots can assist in moving parts, loading things like materials into machines, or pulling things out when they are finished. This is significant, because people can have difficulty doing these jobs all day. Robots can be fast, and accurate, and that kind of guarantee is essential when ensuring that things are made right the first time.

Robots Making Work Faster and More Precise

One major benefit of having robots handle the injection molding is that they are able to manufacture more quickly. Being fast is about spending time and resources wisely. When robots assist in tasks like moving parts or putting materials into machines, they can do it far more quickly than people. This translates into the ability to make more in less time, a huge benefit for companies that need to produce a large amount of a product at a fast pace.

Robots not only make things faster; they also make them safer. They want to get things right. Accuracy is the right thing to do. Robots can do the same thing the same way, every time, which is important, because this reduces the chances that every part they make is exactly the same. This is crucial for products which have to fit together perfectly.

ROBOTS WORK Robots Produce to Meet New Demand

Production is a lot of stuff, fast. Robots may boost production by working all the time without fatigue. They can keep things up day and night, a good way for a company to produce a lot of product quickly. This can be particularly valuable for businesses that need to hit certain deadlines or sell a ton of product.

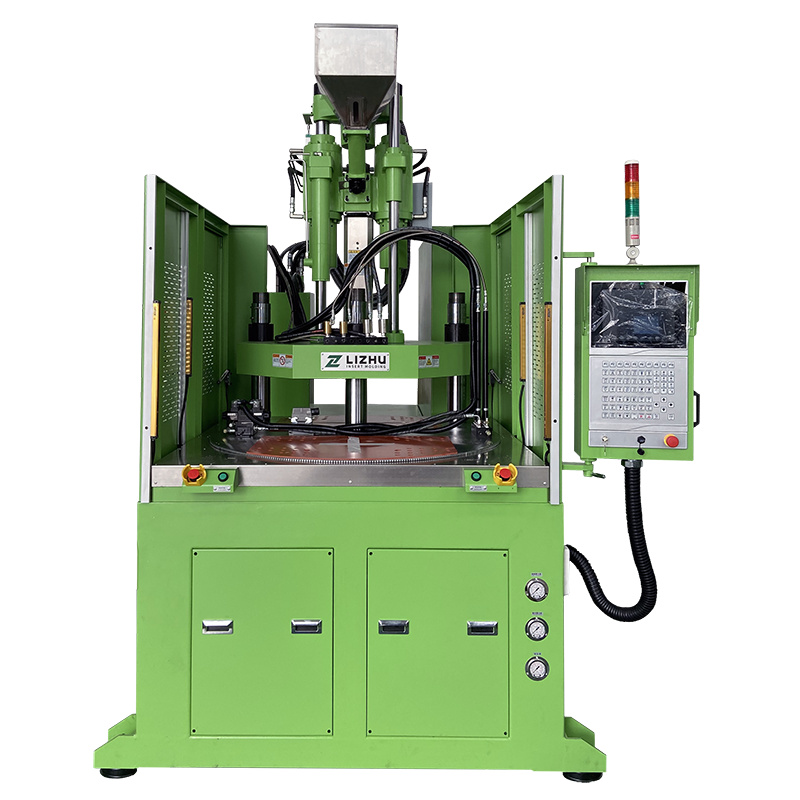

In addition, robots make fully automatic vertical injection moulding machine it possible for companies to save money with the use of injection molding. When robots take over tasks typically done by people, they can do so more cheaply over time. Robots don’t require breaks, holidays, or paychecks like people do. This can help to keep production costs down — and enable companies to earn more money.

Shit Going Fast And Robotically

What is high-speed production? High-speed production is essentially making things really fast. Robots might be useful in this, working much faster than people. They can shuttle parts and materials and high speed vertical injection molding machine take things out much faster than a person. This makes it easy for companies to meet demand and make items more quickly than their competitors.

Advantages of using robots in injection moulding

Above all, applying robots in vertical injection molding has several benefits to enterprises. It speeds things up, makes them more accurate, more efficient. Robots may enhance production, save money, and facilitate rapid production. LIZHU MACHINERY plastic vertical injection moulding machine knows how to deploy robots to ramp up companies’ ability to produce things quickly and with precision. Significance Using robots which are automation devices in injection moulding, a company remains ahead of other companies so that they can also provide their customers with the best of products.